Brush bar trunking system - perfectly adapted, seamless suppliers

Advantages of the OKB open brush bar trunking system

- Trunking along the walls can only be recognised by a narrow brush bar

- Aesthetically pleasing, almost invisible power supply

- Ensures the high-quality appearance of a room

- Hidden cables offer enhanced comfort in your home

- Flexible underfloor system – from planning through to later use

- Can be adapted perfectly to the appropriate room situation

- Can be combined universally with OBO's complete solutions

- Cables exactly where they are needed

Frequently asked questions about the OKB open brush bar trunking system

What are the basic types?

How does the open brush bar trunking system perform with regard to noise transmission?

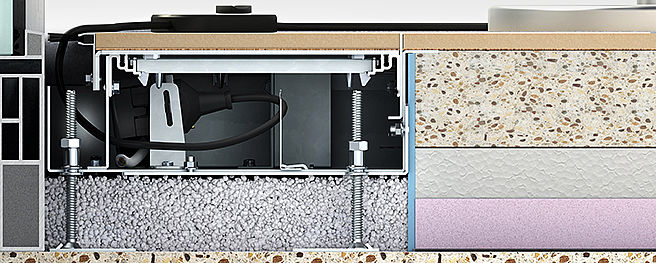

The screed-flush trunking with brush bar is installed at the edge of a side of the room. With regard to footfall noise transmission, the installation of this trunking leads to no worsening of the footfall noise properties in floating cement screen floors. In the case of wall penetrations through partitions with noise protection requirements, noise protection insulation should be installed as required. The air and footfall noise transmission for the OKB brush bar trunking system was evaluated in qualified tests with the MÜLLER-BBM GmbH testing institute in Planegg, Munich.

When is the OKB open brush bar trunking system laid?

The open brush bar trunking system (OKB) is mounted on the raw concrete before the screed work. It runs along the walls for the entire length of the room. The practical fittings of the OKB system allow routing into any corner of the room. Appropriate prefabricated internal and external corners ensure uncomplicated mounting. The system can be adjusted exactly to the planned screed height using the height-adjustment feet.