Underfloor systems

From functionality to aesthetics

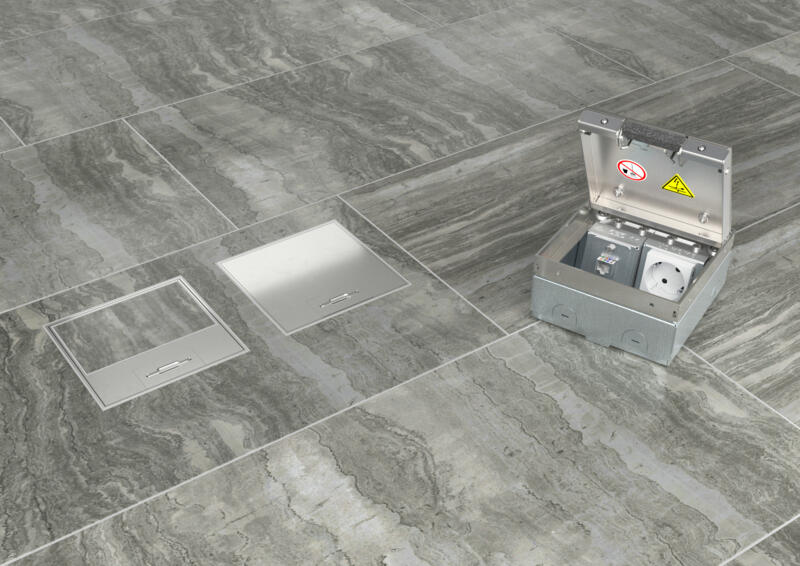

Underfloor systems provide installation space for power, data and multimedia connections in the floor structure. OBO offers underfloor systems for different building types and floor construction techniques, such as screed, raised floors, cavity floors and country-specific floor structures. Various solutions are available, depending on the application.

Your advantages at a glance:

- Proven over many years in office installations, refurbishments of old buildings, exhibition spaces and public buildings

- For dry, moist and wet-care floor coverings

- For the supply of power, data and multimedia technology from the centre of the room

- up to 12 Modul 45® devices in one floor box.

Solutions with trunking systems

Solutions with protective cable pipes

Futurium Berlin

The “House of the Future” is now located between the Charité Hospital and the Office of the Federal Chancellor, in the centre of the government district. Underfloor systems from OBO Bettermann were installed, ensuring a flexible power supply.

Hotel Excelsior Gallia in Milan

OBO Bettermann products blend seamlessly into the elegant details of the Hotel Excelsior Gallia.

Museo della Pietà, Milan

In the Museo della Pietà in Milan, OKA trunking from OBO provide a discreet and flexible power supply around Michelangelo's last masterpiece.

Antwerp Town Hall

Antwerp Town Hall was completely restored between 2018 and 2022. Part of the work: Underfloor systems from OBO. The town hall in Antwerp is listed as a UNESCO World Heritage Site.

Properties of underfloor systems

Load

Wet care

Noise protection

Planning and selection of the correct underfloor system

Standards for underfloor systems

Fire protection in underfloor systems

Support

You might also find this interesting

Innovative design solutions for architects

Discover innovative solutions for architects – tailored electrical installation technology for the highest design and functional requirements.

GES service outlets

Service outlets offer a flexible and discreet solution for the installation of sockets, data connections and multimedia in floor and underfloor systems.

Cassettes: Discreet all-rounders

The flush-floor cassettes combine elegance and robustness for power, data and multimedia connections in high-quality building construction. Perfectly integrated into jointless floor areas.

GES R2 round floor socket – compact & load capacity

The GES R2 round floor socket impresses with its simple design, high load capacity and flexible applications for any room situation.

UDHOME square floor socket – discreet & linear

The UDHOME square floor socket stands for straight-forward and discreet design and flush installation for a stylish integration into any room.

Cable tray systems: industrial charm meets functionality

Simple, robust and stylish: OBO cable trays fit perfectly with the industrial style and can be installed in a flash thanks to patented plug connections. Ideal for modern architecture!